10KW Fiber Laser Cutting Machine for High Power Cutting Stainless Steel

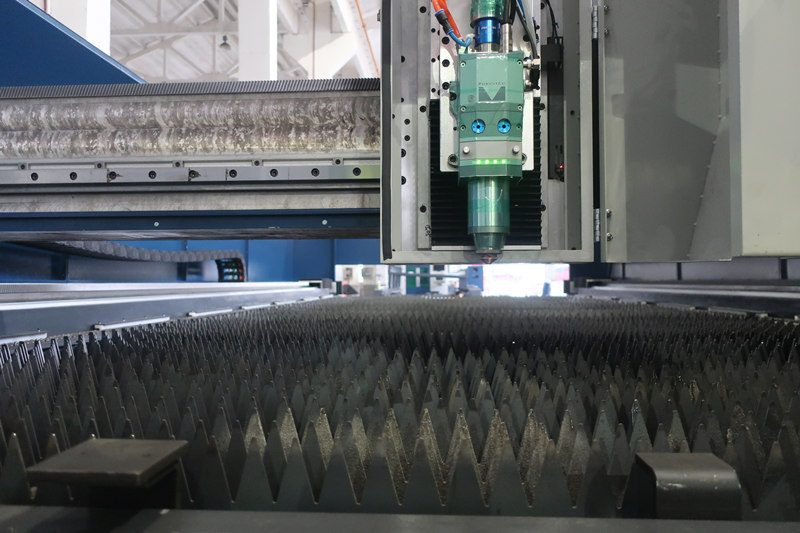

The IPG 10Kw Fiber Laser cutting machines’ ytterbium laser light is created inside the laser unit.Excitation is performed by laser diodes enabling high efficiency with low costs. Laser light created at the resonator is transferred to the cutting head by a fiber optic cable without loss of power or quality. This provides a high beam quality appropriate for metal cutting.

The Power range of resonator source is between 500Wand 6 kW. As the wattage increases so does the cutting speed and capacity respectively.

Fiber Lasers are inherently made for maintenance free production.The importance is sustainable diode life lasting approximately 100,000 hours.

In any defective situation, part changing is easy because modules are designed for plug-n-play.

10KW Fiber Laser Cutting Machine Working Video

Standard Equipments:

√ Germany BECKHOFF CNC Controller

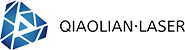

√ IPG YLS-10000W Ytterbium Laser Resonator

√ Advanced PRECITEC cutting head (with air cross blast)

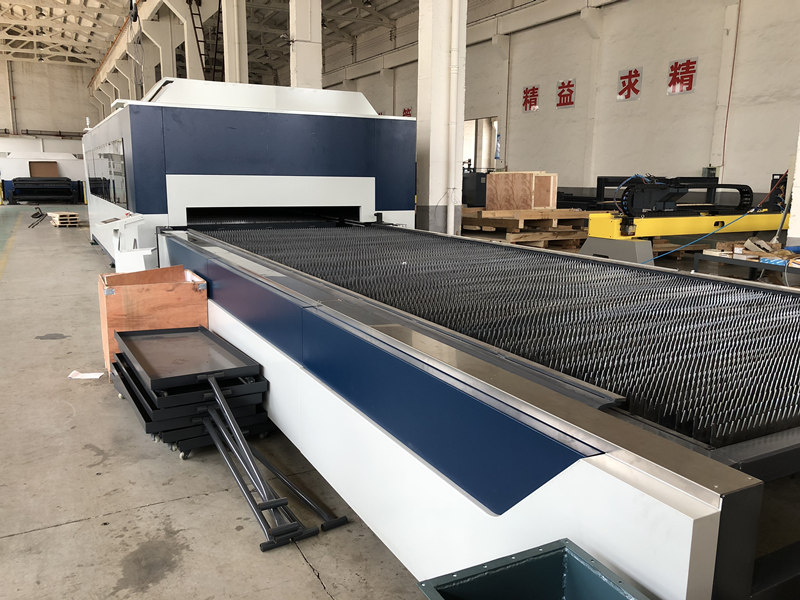

√ Automatic Double Pallet Changer(Shuttle Table)

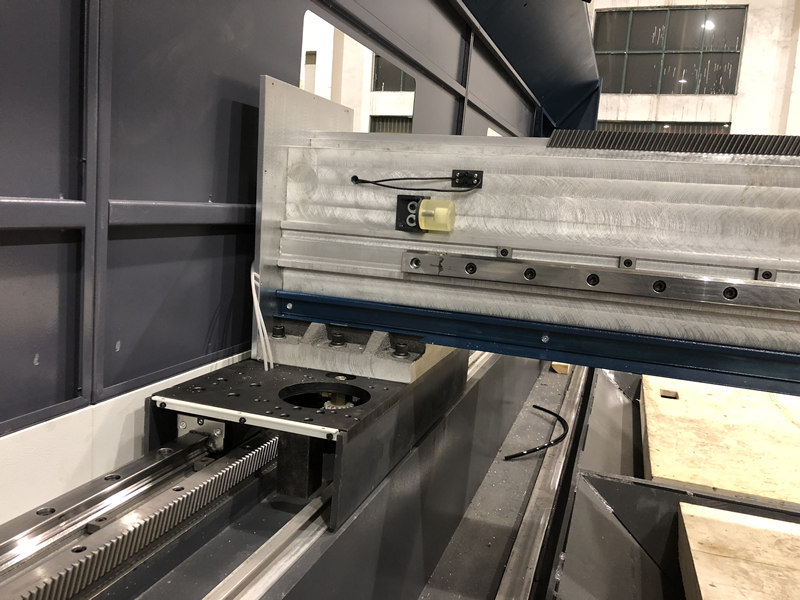

√ Precision Rack & Pinion Drive System (Made in Germany)

√ Radan or Lantek CAD/CAM system

√ Light source

√ Chiller

√ 3 lower protective lenses

√ Operates with both N2 and O2 (cutting) gases

√ Home Position Alignment System

√ Auxiliary Gas Selector

√ Auto Reflection Warning

√ Working Lights

√ 5 Nozzles each of the Following: (1.0mm, 1.2mm,1.5mm, 2.0mm , 2.5mm , 3.0mm)

Optional Equipments:

√ Automatic beam centering system.

√ Linear motor technology

√ Laser Safety Barrier

√ Precitec cutting head

√ Automatic sheet metal loading and unloading system.

√ Compressor

√ 1KW – 2KW – 3KW – 4KW – 5KW – 6KW – 8KW – 12KW Laser power options available.

Maximum cutting thickness:

| available laser sources (1,07μm) | 3kW | 4kW | 5kW | 6kW | 8kW | 10kW | 12kW | |

| carbon steel | [mm] | 20 | 20 | 25 | 30* | 40* | 50* | 60* |

| stainless steel | [mm] | 15 | 20 | 25 | 30* | 40* | 50* | 60* |

| aluminium | [mm] | 12 | 15 | 20 | 30* | 35* | 40* | 50* |

| brass | [mm] | 6 | 8 | 10 | 12 | 15 | 20 | 30* |

| cooper | [mm] | 6 | 6 | 8 | 10 | 15 | 20 | 25 |

* values achieved in conditions dependent on the quality of the material processed, the quality of the cutting gases, the quality of service and the NC program, and the state of the spare parts

Specification:

| Model | [um] | ECO-FIBER-1530 | ECO-FIBER-2040 | ECO-FIBER-2060 |

| length | [mm] | 8900 | 10500 | 14500 |

| width | [mm] | 2320 | 2920 | 2920 |

| height | [mm] | 2150 | 2150 | 2150 |

| weight | [kg] | 15000 | 19000 | 26000 |

| X axis | [mm] | 3060 | 4060 | 6160 |

| Y axis | [mm] | 1540 | 2040 | 2040 |

| Z axis | [mm] | 120 | 120 | 120 |

| max. sheet weight | [kg] | 900 | 1500 | 2500 |